Bridge

Your instrument is equipped with a two-way adjustable Zon bridge. Adjustments to this bridge optimize string height and intonation.

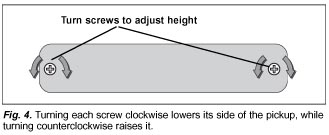

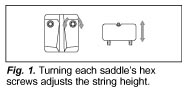

Adjusting string height. Insert the 1.5mm hex key (supplied) into one of the small hex screws located at the corner on each side of the saddles’ leading edge (see Fig. 1).

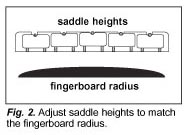

Turning the hex key clockwise raises the saddle, increasing string height. Turning counterclockwise lowers the saddle, decreasing string height. It is important that the saddle heights follow the fingerboard radius for proper playability (see Fig. 2). To check this, sight down the fingerboard from the nut toward the bridge and make sure that the saddles follow the curvature of the fingerboard.

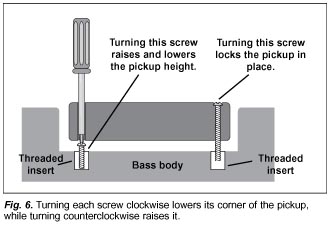

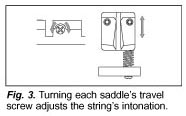

Setting intonation. Adjust the Phillips-head travel screw on the ridge’s back edge (Fig. 3). Rotating this screw counterclockwise moves the saddle forward (toward the neck), causing the string pitch to raise (become sharp). Rotating the screw clockwise moves the saddle backward (toward the bridge), causing the string’s pitch to lower (become flat). The instrument is perfectly intonated when the harmonic at the 12th fret and the fretted note at the 12th fret are equal in pitch.

For more information on adjustments, visit the Zon Guitars web site, at http://www.zonguitars.com.

|

|

|